TECH TALK: January 2026

Choosing appropriate plates and fasteners for an upcoming project should be a simple task. Unfortunately, this is not always the case. Variables such as system type, membrane type, deck type, warranty duration, warranty wind speed, sheet width, and roof height must all be taken into consideration when selecting the correct fastener and plate combination for both insulation and membrane securement. Although the Technical Support provided by Carlisle’s Project Review Department and CSL West can assist with creating an acceptable assembly, it’s important to have a basic understanding of when and where a certain plate or fastener is required.

Plates and fasteners are crucial to a roofing system’s long-term performance. Utilizing the appropriate plate and fastener based on the system and application, achieving minimum fastener penetration depth, installing fasteners designed for the specific deck type, and following minimum warranty requirements for fastening density will help ensure the roof remains secure throughout its expected life cycle. Incorrect use of plates and fasteners, or falling short of minimum warranty requirements for membrane and insulation securement, can be costly due to required warranty repairs—or worse, wind uplift events.

This month’s Tech Talk will provide an overview of Carlisle’s plates and fasteners. The tables and resources below are in accordance with the Carlisle July 2025 Specification and Detail Book. This article is intended to be a one-stop shop for all Carlisle plate and fastener inquiries. Please note that any deviations from Carlisle’s published specifications and details will require prior approval from Project Review.

If you have any questions regarding the contents of this Tech Talk article, please contact Dane Helnore at CSL West.

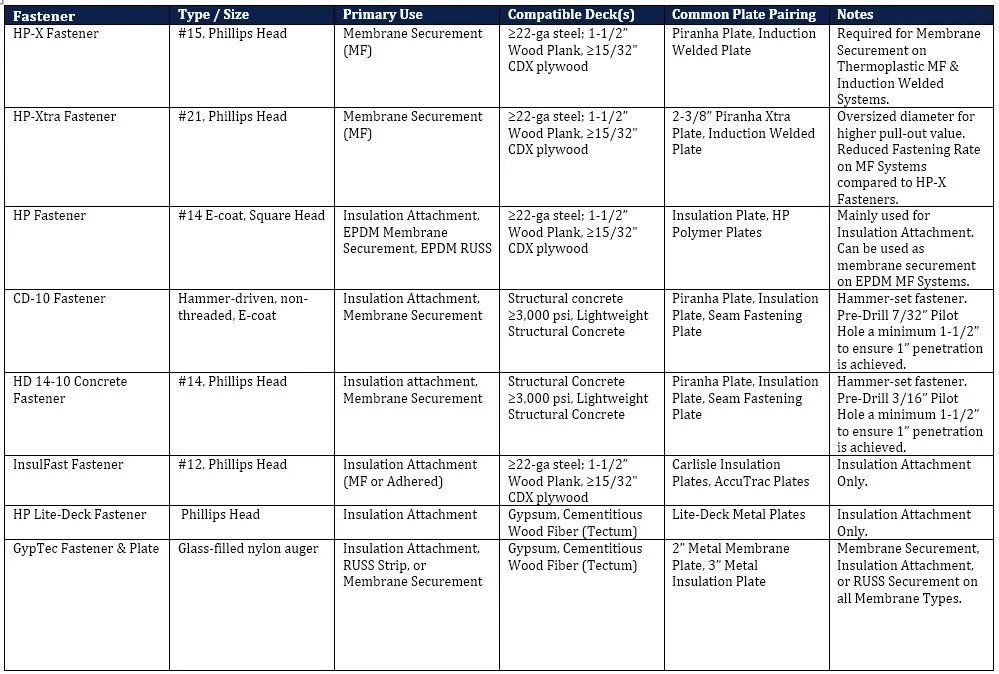

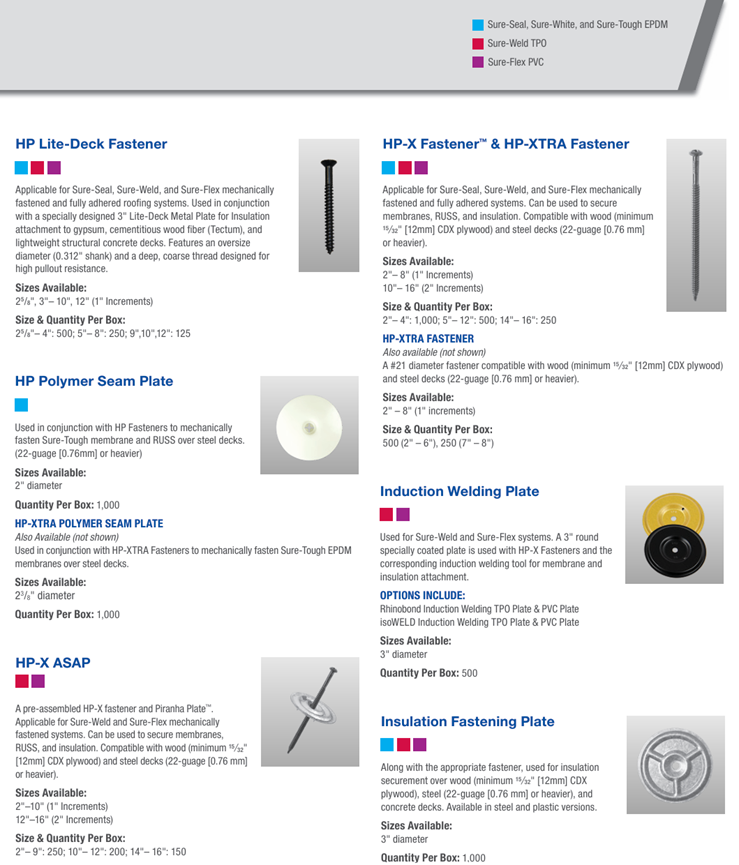

Fasteners:

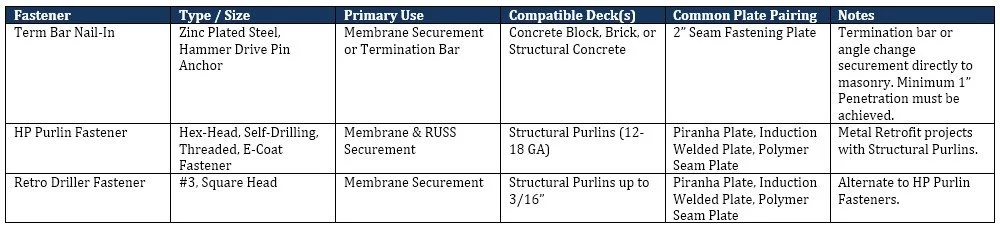

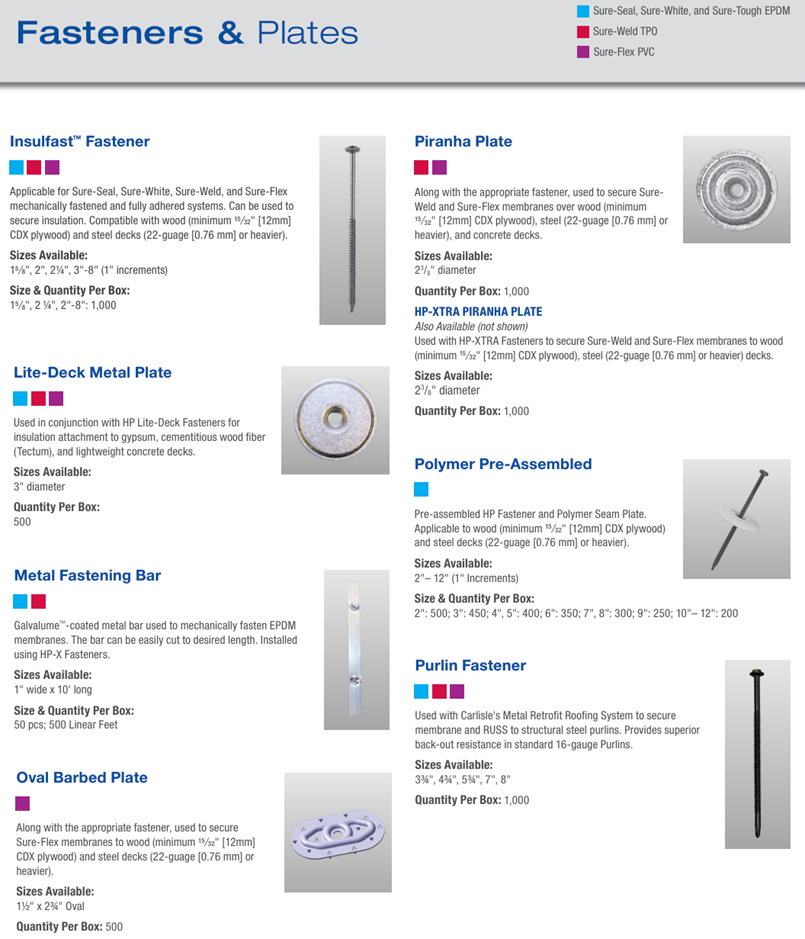

Plates:

Seam Fastening Plates should not be used over in-seam membrane securement over steel decks (MF EPDM Systems). Seam Fastening Plates are still acceptable when used as angle change securement over steel decks.

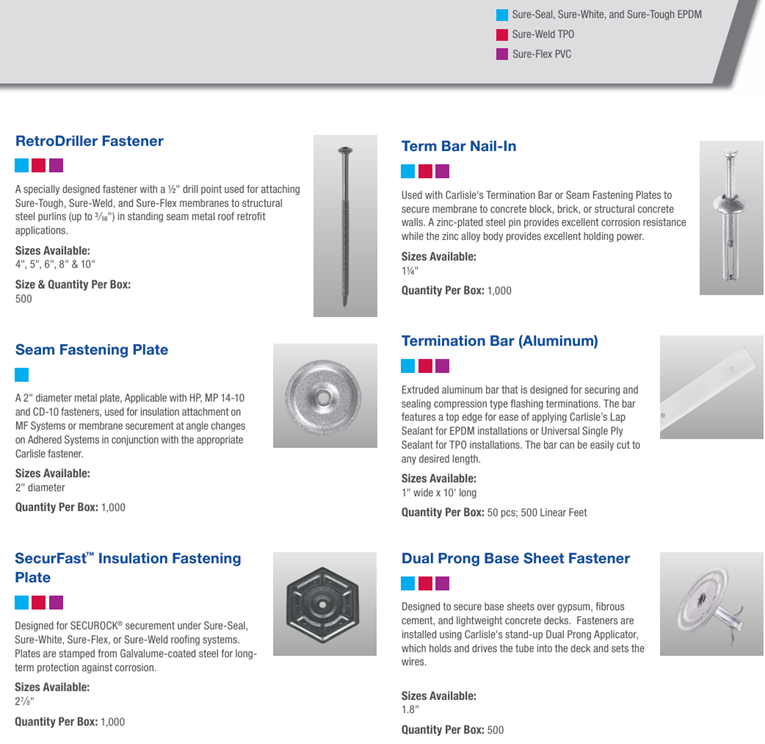

Additional Fasteners & Plates Available:

Pre-Assembled ASAP Insulfast Fastener & Plate: Carlisle’s InsulFast Fastener pre-assembled with 3” diameter plastic plate or metal plate used for insulation attachment only on Adhered and Mechanically Fastened Roofing Systems. Installed using OMG Roofing Products Fastening Tool.

Pre-Assembled ASAP with Polymer Plate: Carlisle’s HP Fastener pre-assembled with 2” diameter Polymer Seam Plate for Reinforced EPDM Membrane Securement on Mechanically Fastened Systems or RUSS Strip Securement over Steel Decks.

Pre-Assembled HP-X ASAP with Piranha Plate: Carlisle’s HP-X Fastener pre-assembled with 2-3/8” diameter Piranha Plate for TPO & PVC Membrane securement over Steel, Wood, and CDX Plywood Decks.

Oval Barbed Plate (PVC): Carlisle’s 1-1/2” x 2-3/4” Oval Barbed Plate used to secure PVC Membrane to Steel, Wood, and CDX Plywood Decks.

Metal Fastening Bar: Carlisle’s Galvalume Coated metal bar used to mechanically fasten Reinforced EPDM Membranes. Must be installed with HP-X Fasteners.

Dual Prong Base Fastener: Designed to secure base sheets over gypsum and fibrous cement. Fasteners are installed using Carlisle’s stand-up Dual Prong Applicator, which holds and drives the tube into the deck and sets the wires.

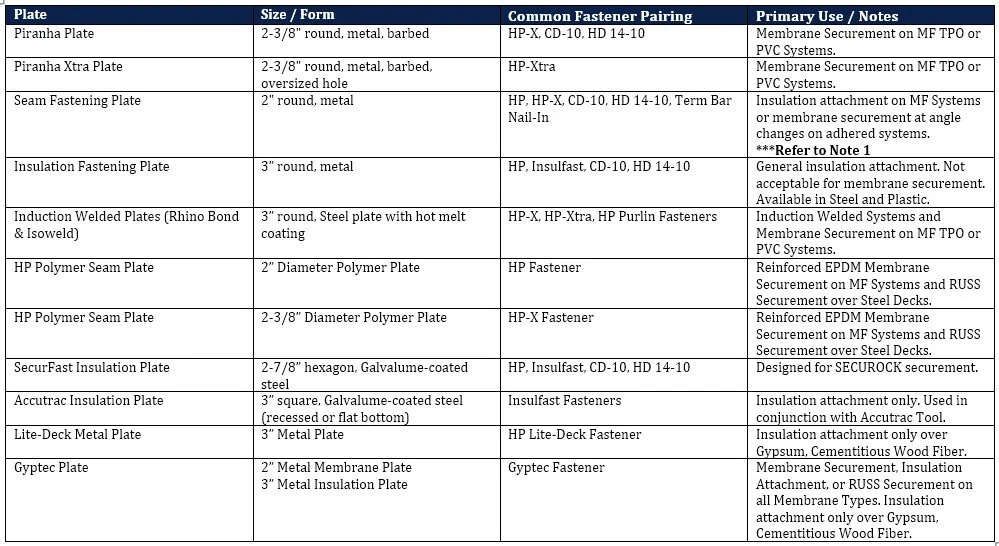

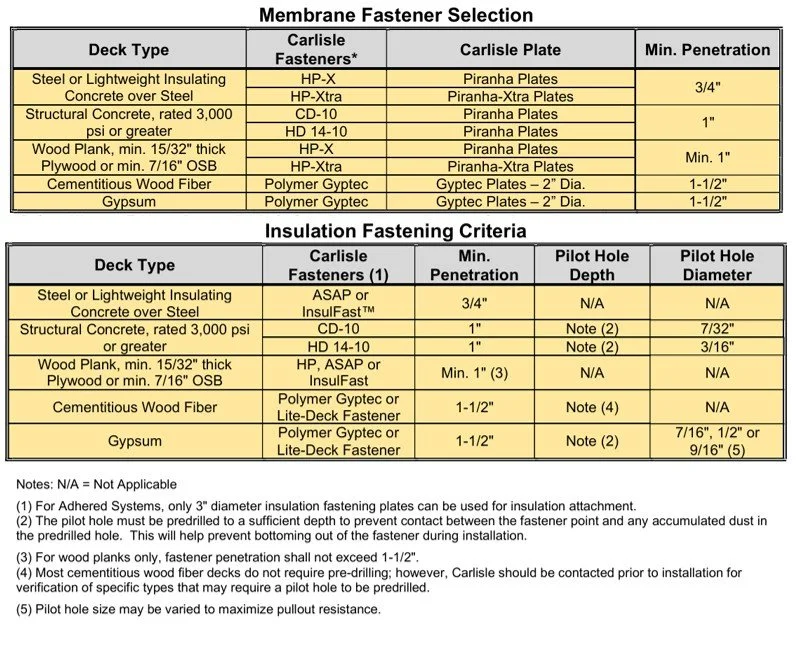

Membrane & Insulation Fastening Criteria, Sure-Seal & Sure-Tough EPDM Membrane:

Membrane & Insulation Fastening Criteria – Sure-Weld TPO & Sure-Flex PVC Membranes:

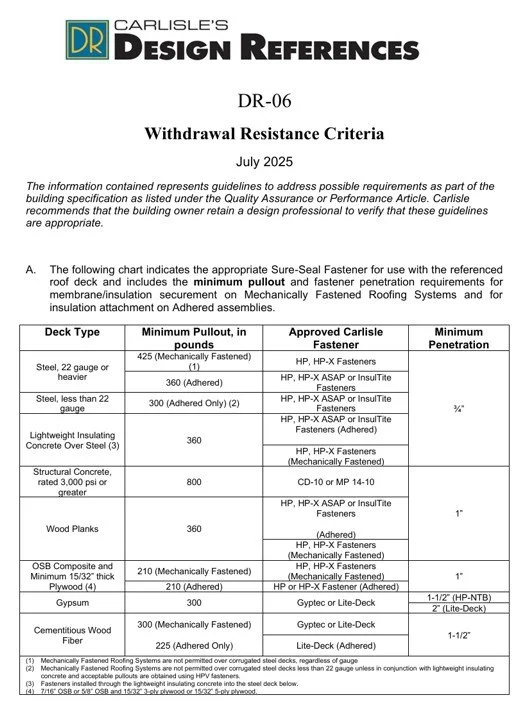

Design Reference DR-06 Withdrawal Resistance Criteria:

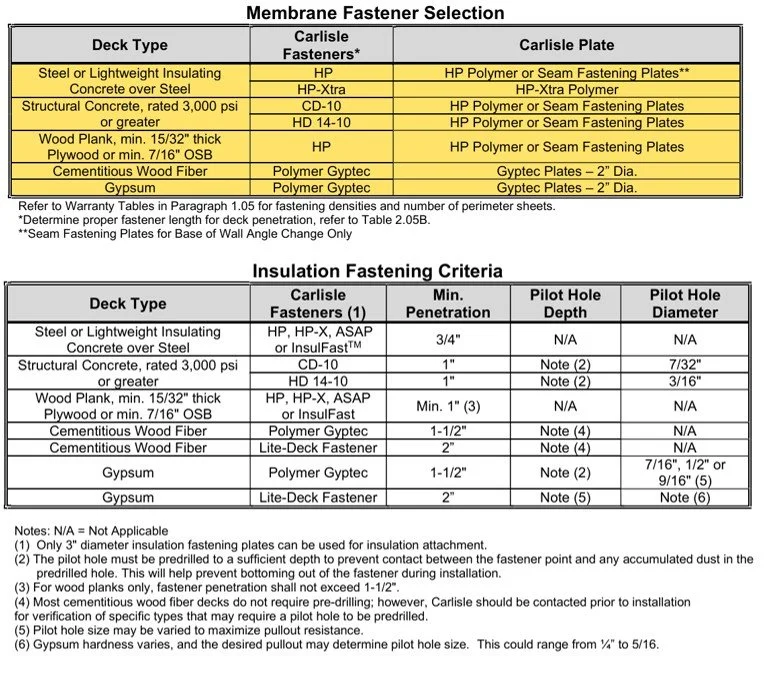

Key Notes / Takeaways:

Membrane Fastening Density on MF Systems can be reduced with appropriate plates and fasteners in certain scenarios

Example: A 20 Year / 80 MPH Warranted Mechanically Fastened TPO System with 10’ Wide Field Sheets and 6’ Wide Perimeter sheets over a steel deck can reduce In-Seam Fastening Rate from 6” O.C. (HP-X Fasteners & Piranha Plates) to 12” O.C. when HP-Xtra Fasteners and Piranha Xtra Plates are utilized.

Insulation Fastening Requirements on Adhered Metal Retrofit Projects with approved Gypsum Coverboard can be reduced with HP-Xtra Fasteners and appropriate insulation plates.

HP Fasteners are only acceptable for Insulation Attachment on TPO & PVC Projects

May be utilized as Membrane Securement on EPDM Projects with acceptable deck type.

HP-X Fasteners and Appropriate Plates must be used for membrane securement on Mechanically Fastened or Induction Welded TPO & PVC Projects over Steel & Wood Decks

HP-Xtra Fasteners and Piranha Xtra Plates are also accepted.

Piranha Plates must be used for Membrane Securement on Mechanically Fastened TPO & PVC Projects

Piranha Plates must also be used for RUSS Strip Securement on Mechanically Fastened or RhinoBond Projects. Oval Barbed Plates are also acceptable in lieu of Piranha Plates on Mechanically Fastened PVC Projects.

2” Seam Fastening Plates can be used as Membrane Securement at angle changes on Adhered EPDM, TPO, and PVC Projects.

Minimum Fastener Penetration Requirements must be achieved regardless of the application.

Pre-Drill Concrete Fastener Pilot Holes beyond Minimum Penetration requirement to avoid fasteners bottoming out due to Dust Accumulation.

2” Polymer Seam Plates must be when installing Mechanically Fastened EPDM Systems over a Steel Deck.

Can not be installed over Securock, DensDeck, or other hard coverboards.

Fasteners suited for Steel Decks can be used to secure Membrane or Insulation to Lightweight Insulating Concrete with Steel Pans.

Minimum fastener penetration requirements for steel decks must also be achieved (3/4”).