TECH TALK: December 2025

Carlisle’s wide range of membranes, system types, and system components gives our contractors a competitive advantage when creating project assemblies. Each project design assembly is thoroughly evaluated by our Project Review Team to ensure that minimum warranty requirements are met and that the system will perform throughout the duration of the warranty. This includes, but is not limited to, fastening patterns, cover board thickness, membrane thickness, substrate preparation, and more.

Although the information provided by our Project Review Team is extremely helpful, not all minimum warranty requirements are included when the NOA is awarded. This Tech Talk will review the minimum perimeter securement requirements for Carlisle’s 90+ MPH windspeed warranties.

90+ MPH Windspeed Warranties

This section of the Tech Talk specifically refers to the perimeter securement of the membrane at the parapet. The fastening pattern, cover board thickness, bead spacing, and number of perimeter sheets/widths/fastening rates will all be provided in the NOA when all necessary project information is submitted into the job file.

Bareback Membranes

Fastening rate of perimeter securement must be enhanced to 6" O.C.

RUSS Strip, in conjunction with the appropriate primer, is still an acceptable method of securement on TPO and EPDM systems.

SAT Membranes

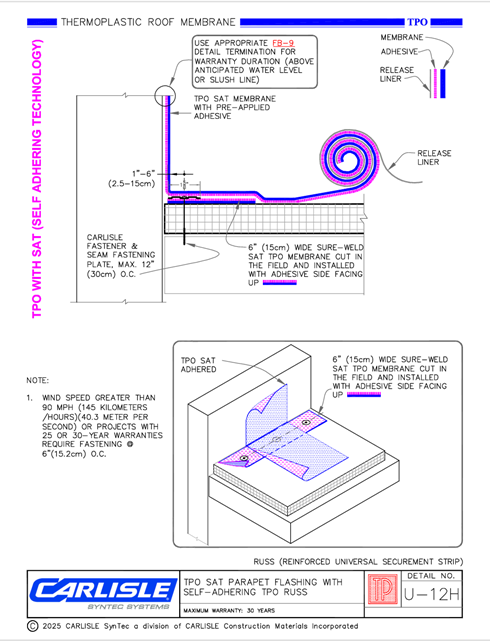

Fastening rate of perimeter securement must be enhanced to 6" O.C. RUSS Strip is an acceptable method of perimeter securement on TPO and EPDM membranes. No primer is required when using RUSS Strip.

Carlisle will also accept a 6"-wide strip of reinforced TPO SAT installed upside down (similar to RUSS Strip) and fastened at 6" O.C. with appropriate plates and fasteners in lieu of RUSS Strip. This detail is only acceptable with TPO SAT membranes. As with the SAT RUSS Strip detail, primer is not required when installing this detail (please refer to Detail U-12H).

FleeceBACK Membranes

Mechanical securement must be used in lieu of a double-bead application of Flex Fast adhesive. This can be achieved in one of the following ways:

6" O.C. mechanical securement of the field membrane using appropriate plates and fasteners.

12" O.C. mechanical securement of the field membrane in conjunction with a double-bead application of Flex Fast adhesive.

12" O.C. mechanical securement of a 9"-wide upside-down FleeceBACK membrane in conjunction with a double-bead application of Flex Fast adhesive (please refer to Details FB-12B.1A and FB-12B.1B).

These details are only acceptable on traditional FleeceBACK membrane, not FleeceBACK RL.

Perimeter securement enhancements are necessary to ensure the assembly will perform properly in a wind event. As mentioned previously, the rate of mechanical securement at the perimeter will not be specified in an assembly letter or job file. It should also be noted that the perimeter securement requirements for projects with warranties greater than 20 years are consistent with the information provided in this Tech Talk.

If you have questions regarding this Tech Talk, please contact Dane Helnore at CSL West.