TECH TALK: October 2025

Mechanically Fastened Thermoplastic (TPO & PVC) Roofing Systems provide a cost-effective option due to reduced material and labor requirements. There are pros and cons to each system type that should be considered when presenting options to an owner. Budget, aesthetics, location, warranty coverage, building use, and deck type/condition are just a few factors that play a role in determining the best roof system candidates. Although limited in warranty type and coverage compared to adhered systems, mechanically fastened systems have an important place in the market.

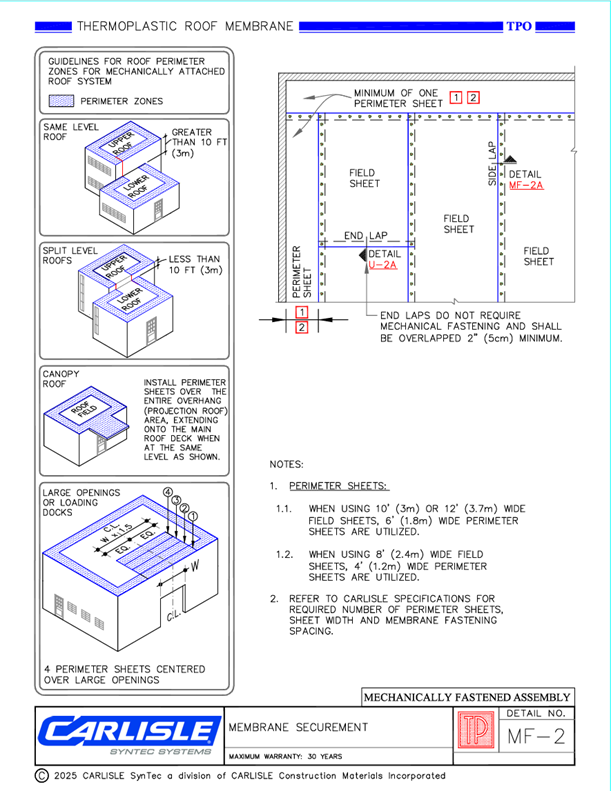

This article provides an overview of various membrane securement methods used when installing thermoplastic roofing systems. The membrane securement methods discussed are acceptable and consistent with the Membrane Fastening Criteria requirements outlined in the Carlisle Specification and Detail Book. Specifically, this article will address methods for creating perimeter sheets on thermoplastic mechanically fastened roofing systems.

What is a perimeter sheet?

At the perimeter of the roof, “half sheets” or “perimeter sheets” are required on a mechanically fastened system. Perimeter sheets provide additional securement to combat wind uplift and prevent fastener withdrawal. Higher wind speed warranties, warranties over 20 years, deck types with low pull-out values, and tall buildings exposed to more wind events will require additional perimeter sheets.

Perimeter sheets can be created by in-seam fastening, using a 10” PS RUSS Strip (TPO only), mechanically securing the membrane and overlaying plates and fasteners with like field membrane, or by using induction-welded plates (e.g., Rhinobond). In this article, we will review in-seam fastening, the 10” PS RUSS Strip, and Rhinobond applications.

Method #1: In-Seam Fastening

In-seam fastening is the most common method of membrane securement on a mechanically fastened TPO or PVC roof. This method is accomplished by installing the appropriate plates and fasteners at a maximum of 12" on center (O.C.) through the edge of the bottom field sheet.

The top field sheet is then overlapped a minimum of 5-1/2" past the edge of the bottom field sheet and heat-welded with a minimum 1-1/2" hot-air weld. In-seam membrane securement must be installed at every field sheet side lap throughout the entire roof system.

Perimeter sheets must be 4' or 6' wide on TPO projects and 40.5" or 5' wide on PVC projects.

Please refer to the Mechanically Fastened TPO Seam Details below, which highlight the minimum spacing requirements in relation to field sheet, plate, and fastener placement, as well as perimeter sheet layout.

Method #2: 10" PS RUSS Strip

The PS RUSS Strip is an innovative product that provides additional mechanical securement while also eliminating field seams. The 10" PS RUSS Strip is secured to the deck and remains in direct contact with the top layer of the system’s underlayment. The backside of the membrane is then cleaned, primed, and mated to the RUSS Strip’s adhesive strips. On mechanically fastened projects, 10" PS RUSS Strips must be installed with Piranha Plates and the appropriate fasteners.

RUSS Strips are installed no greater than 12" on center (O.C.) beneath the center of the field sheet. The field sheet above the RUSS Strip effectively becomes two perimeter sheets. For example, a 12' wide field sheet becomes two 6' wide perimeter sheets. Please refer to Detail MF-2.1 for a visual representation of this concept.

RUSS Strips are not acceptable on warranted PVC projects. Although the 10" RUSS Strip can be used in other TPO applications, this section specifically refers to its use in creating perimeter sheets on mechanically fastened TPO systems. It is crucial to use the appropriate primer—either TPO Primer or Low-VOC EPDM/TPO Primer—when installing RUSS Strips.

Lastly, 6" TPO RUSS Strips are not acceptable substitutes for the 10" TPO RUSS Strip when creating perimeter sheets.

Method #3: Induction-Welded Mechanical Securement

Induction-welded plates and appropriate fasteners provide another acceptable method of membrane securement that can be used in lieu of 10" PS RUSS Strips or in-seam fastening of perimeter sheets. The concept of installing induction-welded plates to create perimeter sheets—rather than using in-seam fastening—is very similar to the 10" PS RUSS Strip method. The induction-welded plates and fasteners are installed no greater than 12" on center (O.C.) beneath the center of the field sheet to create two perimeter sheets.

Sufficient induction welds are critical to roof performance when using this method. Proper calibration of the induction welder, maintaining a level position during welding, cleaning magnets regularly, and ensuring all plates and fasteners are properly welded are pivotal for a successful installation.

This detail represents a slight deviation from what is currently published within Carlisle’s Specification and Detail Book. Please contact your local Field Service Representative if you plan to utilize induction-welded plates and fasteners to create perimeter sheets.

It should also be noted that Carlisle has recently published a new specification allowing for 16' TPO membranes to be mechanically fastened using a hybrid in-seam / induction-welded system. Please refer to the sell sheet below for additional information on this system.

If you have any questions about this article, please contact Dane Helnore at CSL West.