TECH TALK: February 2026

Winter months bring challenges for our industry, including delayed inspections due to snow, product temperature restrictions, and unsafe conditions created by snow and ice on the roof. It is especially difficult to maintain productivity during the winter season in higher-elevation and northern regions of the country. Although these slower months provide a great opportunity to prepare for the year ahead, Carlisle’s innovative products and systems can help teams maintain production throughout the winter.

Option #1: FleeceBACK RapidLock Membranes

Carlisle’s FleeceBACK RapidLock is a revolutionary membrane attachment method that provides a fully adhered EPDM, TPO, or PVC system without the use of adhesives. The RapidLock (RL) system utilizes VELCRO Brand Securable Solutions along with 115-mil FleeceBACK RL EPDM, TPO, or PVC to achieve performance on par with traditional fully adhered single-ply systems. There’s no stirring of adhesives, waiting for flash-off, or temperature restrictions when installing this system. FleeceBACK RapidLock systems also provide up to 80% labor savings compared to traditional bonding adhesive and up to 25% labor savings compared to a traditional FleeceBACK system.

Option #2: SAT Membranes

Sure-Weld TPO SAT comes with a pre-applied adhesive to help you save time and labor while using less product. This 60-mil reinforced membrane is heat-weldable, weather-resistant, and ideal for new construction and re-roofing applications. It provides significant labor savings and is VOC- and odor-free. Sure-Weld TPO SAT is a reinforced membrane laminated to a 100% solids pressure-sensitive adhesive that can be installed in temperatures 25 degrees Fahrenheit and rising. SAT membranes also provide up to 80% labor savings compared to installations using traditional bonding adhesive. SAT TPO membranes are available in White, Gray, and Tan in both 60-mil and 80-mil thicknesses, in 12'-wide and 10'-wide rolls.

Sure-Seal EPDM SAT

Carlisle SynTec Systems is pleased to announce new 20°F (-7°C) cold-weather temperature limits for Sure-Seal SAT (self-adhering technology) non-reinforced and reinforced black EPDM membranes. Both membranes have been formulated to allow for application in colder temperatures, extending the inherent productivity advantages of SAT into the winter months. Carlisle’s SAT EPDM adhesive provides excellent cold-weather tack for wintertime applications. The value of SAT membranes increases during the winter months, when traditional field-applied adhesives take longer to flash off. SAT EPDM membranes are 60-mil thick and are available in 5' x 40', 10' x 50', and 10' x 100' rolls in both black and white.

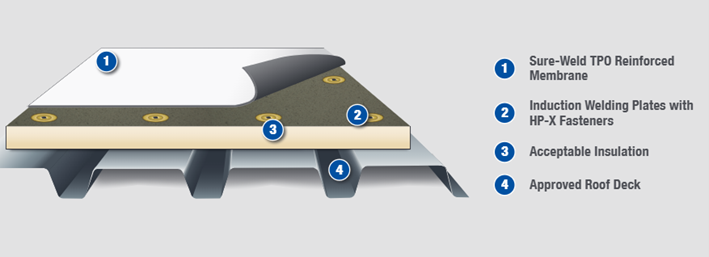

Option #3: Induction-Welded Thermoplastic Systems

This high-performing version of a mechanically fastened installation method utilizes induction welding plates, secured with the help of a portable induction welding tool. Benefits of this installation method include no odors or VOCs, no stirring of adhesives, no waiting for flash-off, and no bonding adhesive temperature restrictions. This system also offers excellent wind uplift performance and is eligible for up to a 30-year / 120-mph wind speed system warranty. As an alternative to a traditional fully adhered roof, it eliminates the need for bonding adhesive without compromising performance.

Option #4: VacuSeal Vented Systems

The VacuSeal Vent Secured Roofing System from Carlisle SynTec Systems is a revolutionary assembly that uses specialized vents to harness the power of the wind to lock roof membranes in place. VacuSeal systems are quick and easy to install, helping save time and labor by substantially reducing the amount of adhesive, ballast, or fasteners required for your project. Carlisle also provides dedicated technical support through a VacuSeal Specialist who assists throughout each phase of the project to help ensure a successful installation. When considering a VacuSeal Vented System for your next project, please reach out to CSL West for more information on how to get started.

For any additional questions regarding this article, please reach out to Dane Helnore at CSL West.