TECH TALK: August 2025

Carlisle offers a wide variety of details for each of its membrane types and systems. Although there are many ways to flash and/or secure a specific detail, Carlisle relies on and enforces the minimum warranty requirements outlined in its published details. It’s important to note that Carlisle will enforce these minimums. However, if a contractor chooses to go above and beyond and install a detail that exceeds the published minimum requirements, Carlisle will have no issue accepting it.

Some minimum requirements can be more difficult to meet than others, especially depending on the condition of the roof (particularly on re-roofs). Carlisle’s published details are ideal when roofing conditions are optimal. This article is intended to highlight some “black-and-white” EPDM details that may help your team navigate the “gray areas” that can often be encountered on the roof.

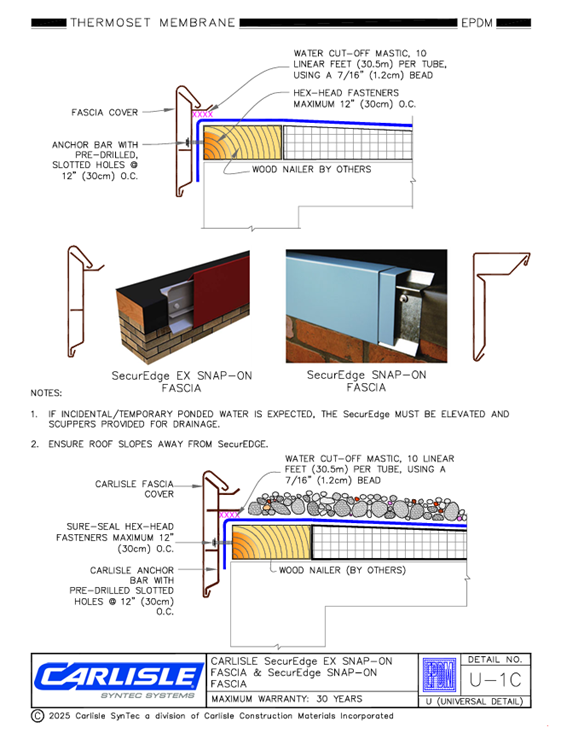

1) Detail U-1C: CARLISLE Securedge EX SNAP-ON FASCIA & SecurEdge SNAP-ON FASCIA

Snap-On Fascia is an excellent option for metal edging at the deck level as well as on top of parapet walls. Aesthetically, Snap-On Fascia will create the appearance of a full Parapet Coping that fully encapsulates the top of the parapet wall when viewed from the ground.

The installation of Snap-On Fascia is much more efficient compared to Parapet Coping as well. Imperfections in the parapet wall framework will not have as much of an impact on the installation of Snap-On Fascia compared to Parapet Coping. Especially if the parapet wall is wider than usual. Consider Snap-On Fascia for your next edge metal solution!

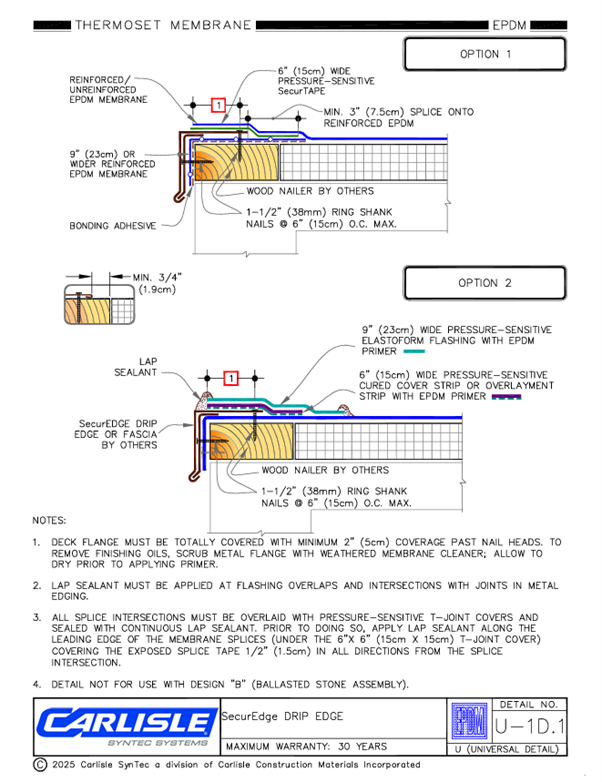

2) Detail U-1D.1: SecurEdge DRIP EDGE

Drip Edge Fascia is a metal edging detail that has proven its performance capabilities throughout the years. Flashing Metal Drip Edge Fascia’s can be done in a variety of ways. Drip Edge Fascia’s installed on roofing systems with Thermoplastic Membranes (TPO & PVC) can either be flashed with Pressure Sensitive Cover Strip and appropriate primer or overlaid with like field membrane and a heat weld if it is Coated Metal.

EPDM has been limited to only utilizing Pressure Sensitive Cover Strip (In conjunction with Elastoform on 30-year warranties) to strip in metal edging. Although it is an excellent flashing option, ice and snow melting off the roof can potentially damage the edge of the cover strip as it slides down and collides with the tape edge. Rather than simply applying sealant to protect the edge of the tape, Carlisle has provided another solution.

Contractors can now splice field membrane onto the metal flanges of the metal edging utilizing 6” SecurTAPE in conjunction with appropriate primer. This will allow for snow, ice, and water to run off the edge of the roof efficiently with no obstruction or “bucking” at the Cover Strip. Please note that Carlisle does require additional 9” or Wider piece of reinforced EPDM to be installed beneath the metal flange which extends down and over the wood nailer. Other minimum requirements should also be noted when installing this detail.

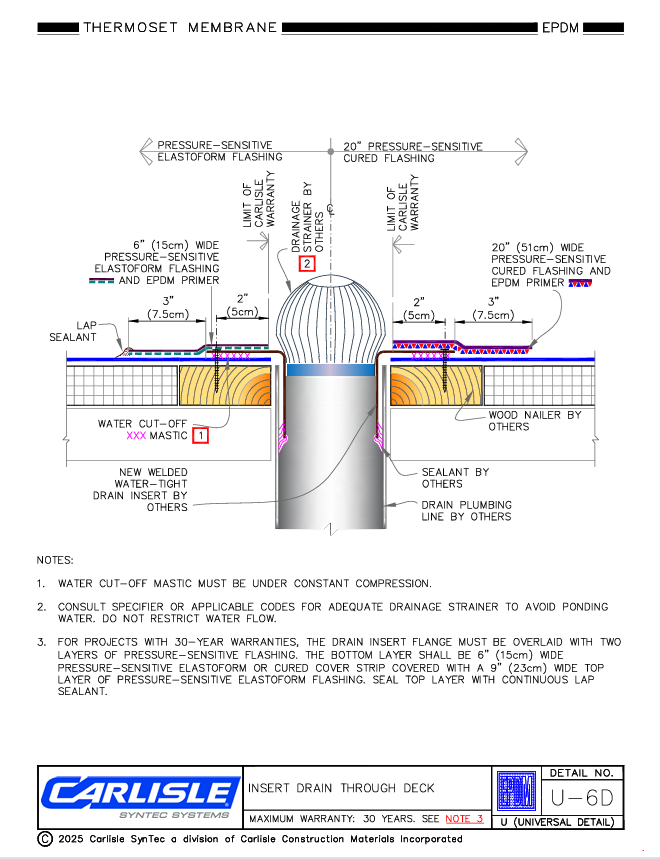

3) U-6D: Insert Drain Through Deck

Carlisle will always prefer drains to be installed with a compression ring and drain bowl which holds water cut-off mastic under constant compression. As mentioned previously, re-roofing scenarios are not always black and white. As an alternative, Carlisle will allow insert drains through the deck in lieu of a compression ring.

Please note that Carlisle will require wood blocking to be installed flush or relatively even with the top of the underlayment. Other Manufacturers, like OMG, make insert drains that can be utilized if the situation calls for it. When insert drains by other manufacturers are used, the extent of the Carlisle warranty ends at the flashing used to overlay the metal flanges.

It is always recommended to reach out to your local Field Service Rep for guidance and approval when considering an insert drain on an upcoming project. The quantity of drains, manufacturers utilized, and warranty information will all be taken into consideration when seeking approval.

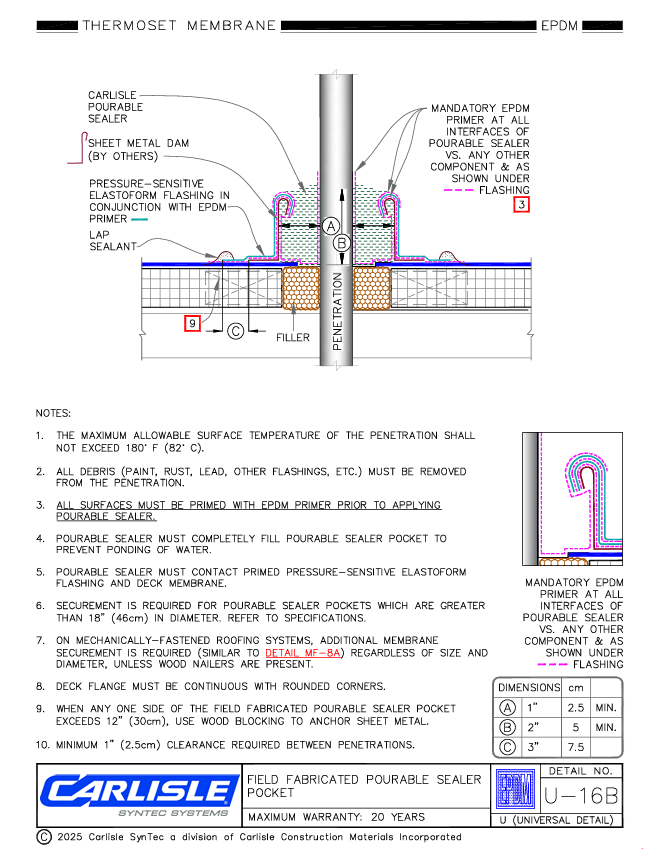

4) U-16B: Field Fabricated Pourable Sealer Pocket

Carlisle’s Pre-Fabricated EPDM Pourable Sealer Pockets are available in the following sizes:

4”: Black

6” Black, White, and Gray

8”: Black and White

Although pourable sealer pockets themselves are an excellent solution for difficult to flash penetrations, 8” Wide Pourable sealer pockets might not be large enough. Even when pourable sealer pockets are “Daisy-Chained” Together, it can still become a difficult installation.

Carlisle will accept Field Fabricated Pourable Sealer Pockets to be installed as required per Detail U-16B. Pockets greater than 18” in Diameter will require additional securement similar to a curb or wall flashing. Penetration spacing and pourable sealer pocket depth requirements still apply (1” between penetrations and pocket wall. 2” minimum pourable sealer pocket depth).

Carlisle will also accept field fabricated pourable sealer pockets with additional flashing to be installed on projects with 30-year warranties. Please refer to Detail U-16B.1 for that detail.

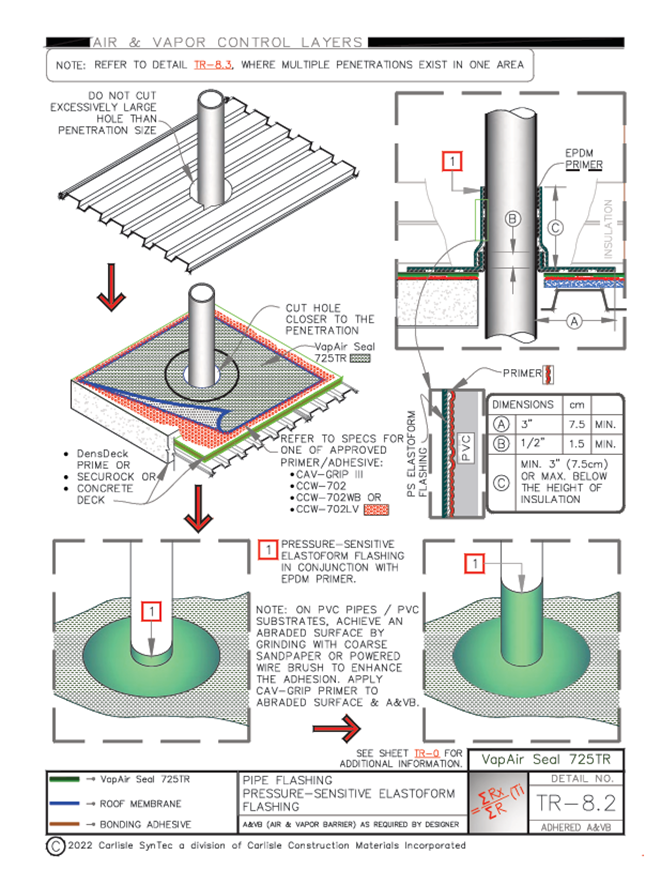

5) TR-8.2: Elastoform on Air and Vapor Barriers

Carlisle does not require air and vapor barriers to be installed on warranted projects. Nor do they inspect air and vapor barriers. Ultimately, it is up to the roofing system specifier, design team, and the contractor to determine where and how an air and vapor barrier is installed. With this in mind, Carlisle does have products and details which can be utilized on an air and vapor barrier install.

One problem-solving detail is the use of Elastoform Flashing to be utilized in lieu of air and vapor barrier membrane when flashing penetrations. Rather than cutting and forming the membrane of an air and vapor barrier which is not malleable, contractors can use Elastoform Flashing in conjunction with primer to flash pipe penetrations prior to installing underlayment.

Using Elastoform in lieu of an air and vapor barrier to flash pipe penetrations can be a time saver compared to being flashed with air and vapor barrier material. Elastoform can be used as an air and vapor barrier material on all Carlisle projects regardless of the membrane type. Carlisle’s Air and Vapor Barrier Field Guides include best practices, product breakdowns, application procedures, etc. A link to Carlisle’s Air and Vapor Barrier Field Guide can be found below:

carlislesyntec.com/document-viewer/air-and-vapor-barrier-field-guide/bMhmtvH5a0C4vg79bPPZ3Q

For any questions, please contact Dane Helnore at CSL West. Your local Field Service Representative is also an excellent resource for identifying, approving, and explaining details that may serve as effective solutions on your next project.